This article is prompted by a concerning trend: some fire safety engineers are presenting sub-par performance solutions for significant deviations from the Deemed-to-Satisfy (DTS) provisions of the National Construction Code (NCC), particularly in travel distances, without employing advanced Computational Fluid Dynamics (CFD) modelling. This approach compromises safety and is not an acceptable solution. In Australia, fire safety engineering has evolved significantly, especially with the adoption of performance-based building codes. The NCC does allow for performance solutions as alternatives to prescriptive DTS provisions. This flexibility enables engineers to develop tailored fire safety strategies that address unique building designs and uses, but it must be exercised responsibly.

What is CFD modelling?

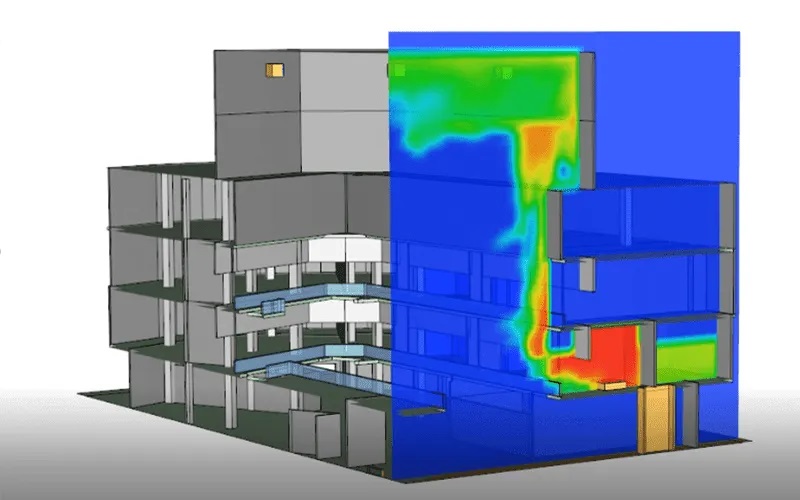

CFD modelling is a sophisticated tool used to simulate fire scenarios smoke movement, tenability conditions, egress/evacuation modelling, and fire suppression system effectiveness. It provides detailed insights into how a fire would behave in a specific environment, which is crucial when proposing performance solutions that deviate significantly from standard provisions.

Figure from Australian Fire Engineering Guidelines

Advantages of using CFD in Fire Safety

- Detailed and accurate predictions: provides a high-resolution analysis of fire dynamics and their impact on building safety

- Enhanced design flexibility: enables engineers to explore innovative building designs and ensure safety through performance-based compliance

- Risk mitigation: identifies potential hazards early in the design process, allowing for corrective measures before construction

Limitations and considerations

While CFD modelling is an invaluable tool, it has some limitations:

- Computationally intensive: simulating complex scenarios can be time-consuming and requires significant computational resources

- Expertise required: accurate CFD modelling demands specialized knowledge in fluid dynamics, heat transfer, and fire behaviour

- Validation: results need to be validated against real-world fire test data or established benchmarks to ensure reliability

When is CFD modelling required?

CFD modelling provides detailed insights into how a fire would behave in a specific environment, which is crucial when proposing performance solutions that deviate from standard provisions. They key strength of CFD modelling is that it is quantitative in lieu of qualitative

Advanced CFD modelling is typically required when:

- Significant deviations from DTS Provisions: proposals involve substantial increases in travel distances or alternative egress strategies. I.e., anything over 40m to a point of choice and 60m to an exit in a typical office

- Complex building designs or hazards: structures with unique architectural features, large open spaces, unconventional layouts or those with high hazards like large quantity of combustibles stored, large batteries, fuel storage, etc

- High occupant loads: buildings expected to accommodate large numbers of people, where evacuation dynamics are critical

- Specific Fire Safety objectives: situations where standard fire safety measures are insufficient to meet the desired safety outcomes

For example, in warehouse buildings, CFD modelling is often employed to justify performance solutions related to significant extended egress travel distances and the distance between exits. The modelling demonstrates that, despite the deviations, the smoke exhaust system and overall design maintain tenable conditions for occupants during evacuation.

Early stakeholder consultation is key

There are many stakeholders that are required to be consulted for a fire engineered performance solution. You cannot leave any stakeholder in the dark, from the end user to building owners, insurers, architects, principal contractor, NCC consultant and most importantly the Principal Certifier. It is common knowledge that different stakeholders will have different priorities, and this is why the performance-based design brief (PBDB) stage is so crucial and was written into the NCC within clause A2G2(4).

Without the acceptance of the proposed performance solutions and proposed methodologies by the stakeholders in the PBDB stage, the solution cannot proceed to the analysis phase.

Figure from Australian Fire Engineering Guidelines

MBC Group recommendation

We advocate for proactive communication early in the design phase with a collaborative approach to ensure there are no surprises for stakeholders that shoot down the proposed performance solution. Experience has taught us that stakeholder management is one of 5 most common challenges that is seen on every project. Re-engineering, delays and poor client satisfaction may be avoided by a quick phone call at the concept stage, asking the Principal Certifier are you comfortable without CFD modelling for ‘x,y,z solution’?