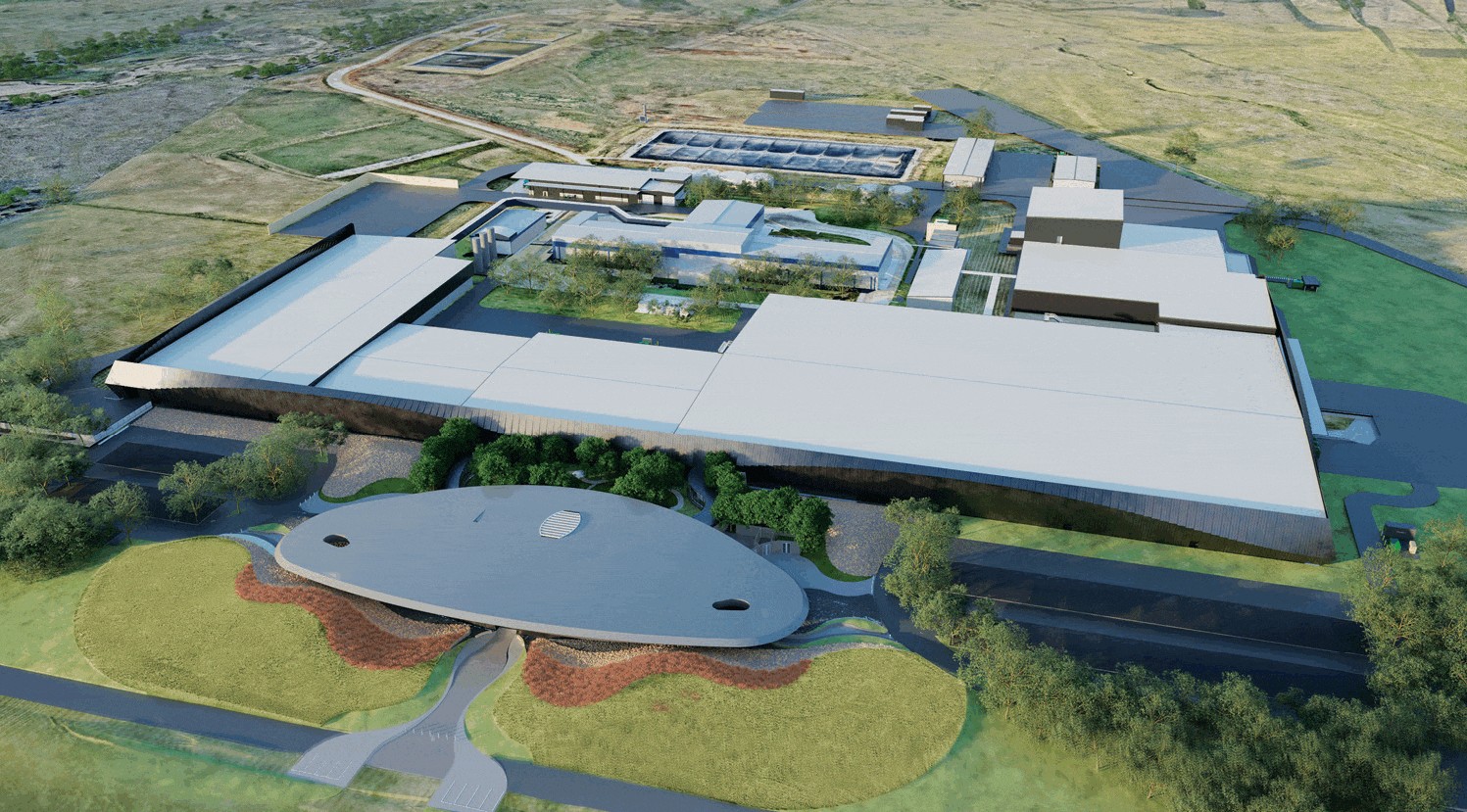

Baiada Oakburn Processing Facility

Client

Project Size

Value

Delivering a next-generation poultry processing facility at Oakburn that is designed for a throughput of up to 3 million birds/week involves far more than 'big shed' compliance. This development integrates some key issues:

- High-intensity industrial processing, cold storage and distribution

- Complex essential services and food-industry safety systems

- Staging and commissioning pressures typical of large-format manufacturing

- Heightened stakeholder sensitivity around regional impacts often associated with major agribusiness projects (traffic movements, utilities demand, environment interface), particularly under an SSD planning framework

For a facility of this scale (described as one of the largest of its kind in the region), certification needs to be rigorous, coordinated and predictable so construction momentum is maintained. As Accredited/Principal Certifier, our focus was to ensure we were clear, consistent and contactable throughout delivery, aligning design intent, construction sequencing, and evidence capture so the project could progress with confidence. We developed a straightforward approach;

1) Compliance strategy aligned to a high-throughput industrial plant

We established an approvals and inspection framework suitable for a large processing footprint (processing, chilling, cold storage, distribution, plant areas, and ancillary buildings) and confirmed certification pathways and documentation standards early to reduce rework during peak construction.

2) Staged works and evidence-led inspections

Structured a staged inspection program to suit progressive completion and commissioning (typical for complex industrial projects), with clear hold points and traceable evidence packs for critical elements (structure, fire safety measures, egress, services integration).

3) Coordination across disciplines and stakeholders

Worked collaboratively with the project team to resolve certification questions quickly and keep the build moving—particularly where industrial equipment, automation and building systems interface (often a risk area late in delivery on facilities aiming for advanced processing performance).

4) Practical compliance outcomes

Maintained a consistent interpretation of NCC requirements and certification evidence expectations across the build, reducing ambiguity for contractor teams and supporting reliable project programming.

MBC Group supported Baiada’s major Oakburn investment with disciplined, evidence-led certification, helping a complex, high-throughput processing facility progress toward 2026 operations.

Like reading about our projects?

Contact us to discuss your proposed development and find out how we can deliver outstanding results for your development.